Simplifying Measurements with a High-Accuracy Optical Fibre Diameter Analyser

Simplifying Measurements with a High-Accuracy Optical Fibre Diameter Analyser

Blog Article

Enhance Your Fiber Optic Projects With a Reliable Diameter Analyser

The combination of an effective diameter analyser into fibre optic tasks acts as a critical element in attaining accuracy and uniformity. By facilitating accurate size measurements, these analysers not only enhance the quality of installments yet also reduce prospective compatibility concerns amongst parts. Furthermore, the innovative capabilities of modern-day analysers simplify information collection and quality assurance procedures. As we discover the critical functions and advantages of these tools, it becomes noticeable just how they can change task outcomes and make sure adherence to industry criteria. What remains to be talked about is how to properly carry out these analysers in your existing operations.

Importance of Diameter Dimension

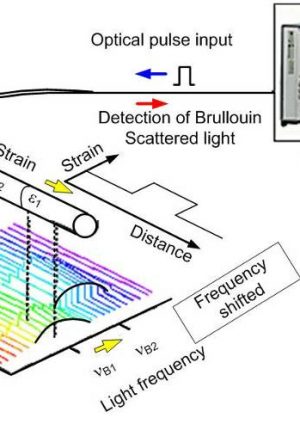

Measuring the size of fiber optic wires is a vital task that makes certain optimum efficiency and dependability in communication systems. Precise diameter dimension is vital for different reasons, primarily for maintaining signal integrity and minimizing loss. A cable's size straight affects its capacity to send light properly; inconsistencies from the specified diameter can lead to increased depletion, which impacts the overall efficiency of the network.

Moreover, accurate measurement is crucial during the installation and maintenance of fiber optic systems. An inappropriate fit in between connectors and wires can cause signal deterioration or full failure of interaction links. By ensuring that diameters are within specified tolerances, technicians can enhance compatibility in between parts, leading to improved system integrity.

Additionally, diameter measurement plays a significant duty in top quality control during manufacturing. Consistency in the diameter of fiber optic cable televisions is important for making sure uniform performance across various sets. optical fibre diameter analyser. This consistency aids makers preserve sector requirements and fosters confidence amongst end-users

Functions of an Efficient Analyser

An effective analyser for fiber optic tasks must incorporate a number of crucial features that enhance accuracy and functionality in diameter measurement. High-resolution optical sensing units are important for precise diameter readings, enabling individuals to detect also the least variants in fiber thickness. These sensing units need to be complemented by innovative calibration systems, guaranteeing consistent performance throughout various problems and products.

Secondly, a straightforward interface is vital for helping with simplicity of operation. This includes intuitive software program that allows for smooth data input and outcome, together with visual representations of the measurements taken. A portable layout boosts usability in various area atmospheres, making it simpler to carry out evaluations on-site.

Furthermore, the analyser ought to support several measurement modes, accommodating different fibre kinds and applications. The capability to shop and get historic information is one more important attribute, allowing individuals to track performance in time and make notified decisions.

Benefits for Fiber Optic Projects

Carrying out a size analyser in fibre optic tasks supplies considerable advantages that substantially improve project effectiveness and high quality. One of the key benefits is the ability to make certain specific dimensions of fibre size, which is crucial for keeping optimum performance in fibre optic systems. Exact size readings aid in the identification of incongruities that can cause signify destruction or loss, therefore guaranteeing premium transmission.

Additionally, using a size analyser enhances the quality assurance process. By automating dimension jobs, project groups can decrease the moment spent on hand-operated evaluations, leading to faster task completion and reduced labour prices. This effectiveness also permits for more strenuous testing methods, leading to improved item dependability.

Moreover, uniformity in fibre diameter dimensions promotes compatibility with other fibre optic parts, reducing the danger of installment errors and boosting general system efficiency. The unification of a size analyser not only aids in keeping sector requirements but also fosters confidence in project deliverables.

Assimilation Into Existing Workflows

Integrating a size analyser right into existing operations can dramatically improve the operational performance of fibre optic tasks. By seamlessly incorporating this modern technology, groups can accomplish specific measurements that are vital to maintaining the stability and efficiency of fiber optic systems. This assimilation permits real-time data collection and analysis, which can be Full Report critical during the manufacturing and installment phases.

Moreover, the capability to automate size dimension processes lowers the possibility for human error, guaranteeing consistent top quality control throughout the project lifecycle. The data generated can be quickly shared across platforms, promoting collaboration among designers, technicians, and task supervisors. This ease of access boosts decision-making and increases task timelines.

Choosing the Right Diameter Analyser

When selecting a diameter analyser for fibre optic projects, it is important to consider numerous essential elements that straight impact dimension accuracy and functional performance. The resolution and precision of the Learn More analyser need to line up with the specific requirements of your job. Higher resolution instruments can identify minute variants in size, which is essential for ensuring ideal efficiency in fiber optic systems.

Next, assess the speed of dimension. For jobs with limited target dates, a diameter analyser that uses rapid data purchase can significantly enhance efficiency. In addition, consider the analyser's compatibility with existing systems and software. A seamless integration reduces configuration time and minimizes disturbances throughout procedures.

One more crucial variable is the series of diameters the analyser can fit. Make certain that the picked tool can deal with the certain sizes of fiber optics you are functioning with, as well as any potential future demands. Evaluate the supplier's support and guarantee offerings. When looking for or fixing aid, trusted consumer service and technical assistance can show important. By meticulously evaluating click to read these factors, you can select a size analyser that improves the effectiveness and accuracy of your fiber optic projects.

Verdict

In verdict, the assimilation of a reliable diameter analyser is critical for improving fibre optic jobs. Exact diameter measurements make sure optimum efficiency and dependability while decreasing installment errors (optical fibre diameter analyser).

A wire's size directly influences its capability to transmit light properly; variances from the defined diameter can lead to boosted depletion, which influences the general performance of the network.

Report this page